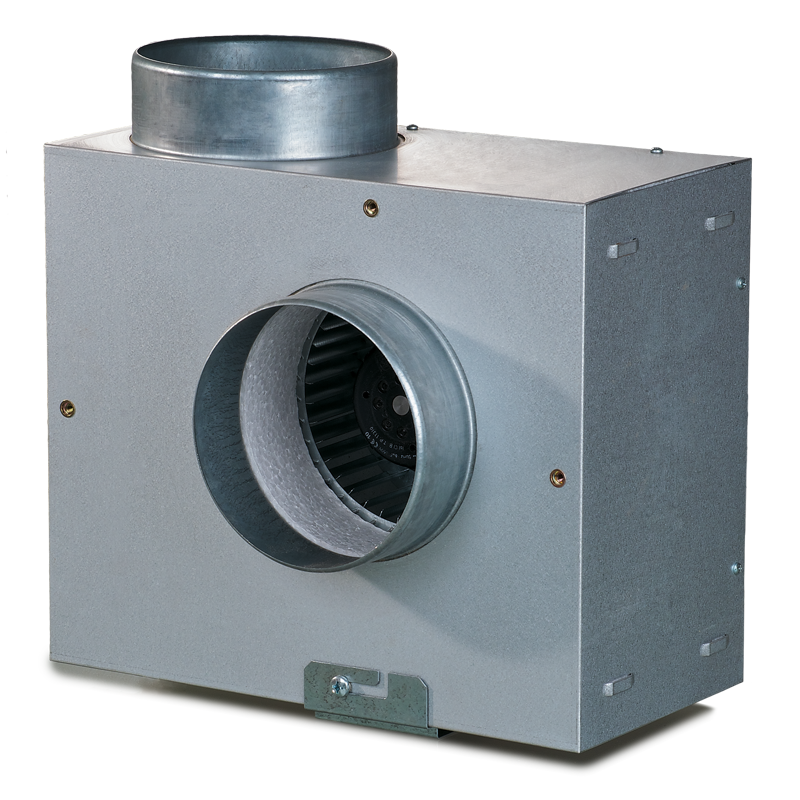

VENTS KSA 100-2E (220/60)

- Description

- Characteristics

- Downloads

- Dimensions

- Additional diagrams

- Designation key

| APPLICATIONS | |

|

|

| DESIGN | |

|

|

| MOTOR | |

|

|

| SPEED CONTROL | |

|

|

| MOUNTING | |

|

|

|

THE FAN WITH ELECTRONIC TEMPERATURE AND CONTROL MODULE (U OPTION)

|

|

|

|

|

|

|

Control logic of the fan with the electronic temperature and speed control module

|

|

|

|

| There are three switch delay patterns for various cases: | |

|

|

|

|

| VENTS KSA fan greenhouse ventilation example | |

| Parameter |

KSA 100-2E (220/60) |

Measurement unit |

|---|---|---|

| Engine Type | 220V / 60Hz | - |

| Phase | 1 | ˜ |

| Voltage | 230 | V |

| Frequency | 60 | Hz |

| Sound pressure level at 3 m distance | 65 | dBА |

| Pressure | 476.3 | Pa |

| Power consumption | 128 | W |

| Maximum air capacity | 387 | m³/h |

| Maximum transported air temperature | 25 +40 | °С |

| Protection rating | IP X4 | - |

| Weight | 4.22 | kg |

| Spigot size | 100 | mm |

| Number of poles | 2 | - |

| Parameter | Value | Measurement unit |

|---|---|---|

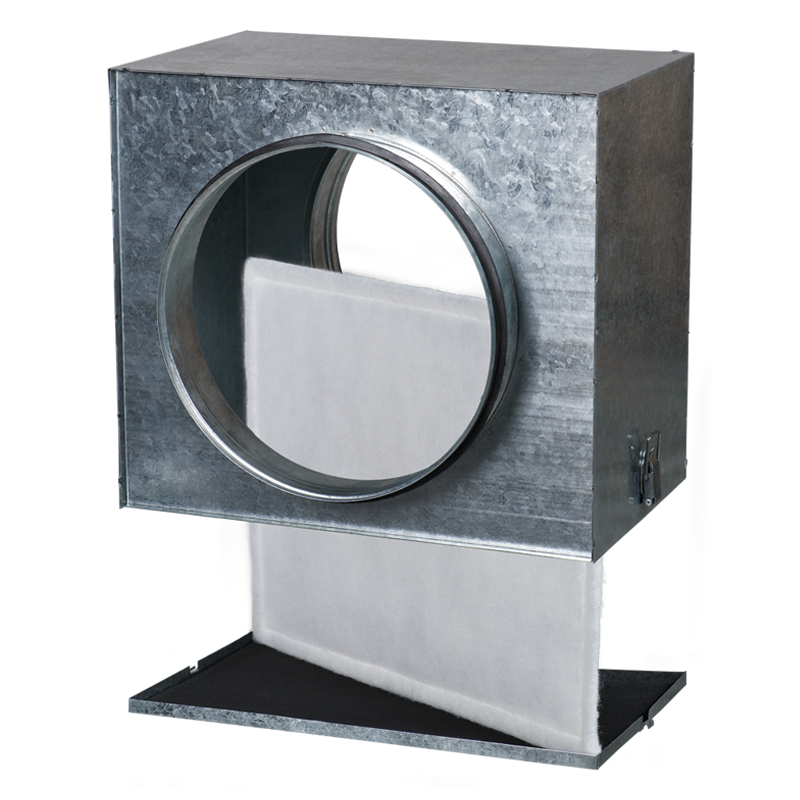

| ∅D | 99 | mm |

| B | 184 | mm |

| H | 308 | mm |

| Р | 48 | mm |

| L | 310 | mm |

| Series | Spigot diameter | Polarity | Phase | Options |

| VENTS KSA | 100; 125; 150; 160; 200 | 2, 4 | Е: single phase | U: speed controller with an electronic thermostat and a temperature sensor integrated inside an air duct. Temperature-based operation logic. Un: speed controller with an electronic thermostat and a temperature sensor fixed on a 4-meter cable. Temperature-based operation logic. U1: speed controller with an electronic thermostat and a temperature sensor integrated inside an air duct. Timer-based operation logic. U1n: speed controller with an electronic thermostat and a temperature sensor fixed on a 4-meter cable. Timer-based operation logic. U2: speed controller with an electronic thermostat and a temperature sensor integrated inside an air duct. Temperature-based switching on/off. U2n: speed controller with an electronic thermostat and a temperature sensor fixed on a 4-meter cable. Temperature-based switching on/off. R1: power cord with a mains plug. P: integrated smooth speed controller. |

Domestic fans

Domestic fans  Industrial and commercial fans

Industrial and commercial fans  Single-room ventilation systems with heat recovery

Single-room ventilation systems with heat recovery  Air handling units

Air handling units  Air heating systems

Air heating systems  Air sterilizers

Air sterilizers  Smoke extraction and ventilation

Smoke extraction and ventilation  Accessories for ventilating systems

Accessories for ventilating systems  Electrical accessories

Electrical accessories  Ventilation ducts and fittings

Ventilation ducts and fittings  Air distribution components

Air distribution components  Ventilation kits and vents

Ventilation kits and vents