VENTS MICRA 80 A3

- Description

- Characteristics

- Downloads

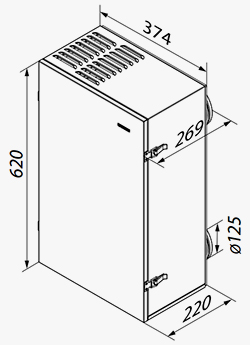

- Dimensions

- Dimensions

- Accessories

- Ventilation system arrangement

Description

Description

| FEATURES | |||

|

|

||

| OPERATING LOGIC | |||

|

|

||

| CONTROL AND AUTOMATION | |||

|

|

||

|

|||

Characteristics

Characteristics

| Parameter |

VENTS MICRA 80 A3 |

Measurement unit |

|---|---|---|

| Speed | 3 | - |

Voltage  |

230 | V |

| Phase | 1 | - |

| Power | 57 | W |

| Air capacity | 80 | m³/h |

Frequency  |

50 | Hz |

| Unit current | 0.34 | A |

Air capacity  |

40 | m³/h |

| Heat recovery efficiency | 77 | - |

| Sound pressure level at 3 m | 24 | dBА |

Casing material  |

- | |

Insulation  |

- | |

Insulation thickness  |

15 | mm |

| Filter: extract | G4 | - |

| Filter: supply | G4 | - |

| Remote control panel | Mechanical | - |

Heat exchanger type  |

- | |

| Heating | without heating | - |

Heat exchanger material  |

- | |

| Duct | 125 | - |

Heat recovery efficiency  |

% | |

Max. transported air temperature  |

°С | |

Weight  |

17 | kg |

Files archieve

Downloads

Select document type

Dimensions

Characteristics

| Parameter | Value | Measurement unit |

|---|

Dimensions

Dimensions

Accessories

Accessories

|

|

|

||

| Round Ø 125 mm telescopic air duct, adjustable length from 500 up to 1000 mm | MVM 122 bVs N stainless steel outer hood | SF 195х195х6 G4 filter |

Ventilation system arrangement

Ventilation system arrangement

|

|

|

|

|

|

Domestic fans

Domestic fans  Industrial and commercial fans

Industrial and commercial fans  Single-room ventilation systems with heat recovery

Single-room ventilation systems with heat recovery  Air handling units

Air handling units  Air heating systems

Air heating systems  Air sterilizers

Air sterilizers  Smoke extraction and ventilation

Smoke extraction and ventilation  Accessories for ventilating systems

Accessories for ventilating systems  Electrical accessories

Electrical accessories  Ventilation ducts and fittings

Ventilation ducts and fittings  Air distribution components

Air distribution components  Ventilation kits and vents

Ventilation kits and vents