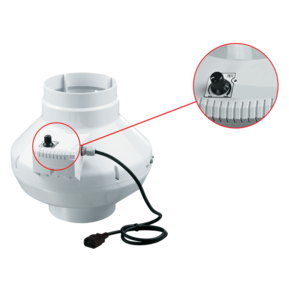

VENTS VK 200

Inline centrifugal fan in plastic casing with the air flow up to 890 m³/h.

- Description

- Characteristics

- Capacity diagram

- Downloads

- Dimensions

- ADDITIONAL TECHNICAL DATA

- Designation key

- Video

Description

Description

| APPLICATIONS | |

|

|

| DESIGN | |

|

|

| MOTOR | |

|

|

| SPEED CONTROL | |

|

|

| MOUNTING |

VK fan kitchen exhaust ventilation example |

|

|

| THE FAN WITH ELECTRONIC TEMPERATURE AND CONTROL MODULE (U OPTION). | |

|

|

| CONTROL LOGIC OF THE FAN WITH THE ELECTRONIC TEMPERATURE AND SPEED CONTROL MODULE | |

|

|

| There are two switch delay patterns for various cases: | |

|

|

| Example for temperature sensor delay pattern: | Example for timer delay pattern: |

|

|

|

|

| ↓ | ↓ |

|

|

| ↓ | ↓ |

|

|

| ↓ | ↓ |

|

|

| ↓ | ↓ |

|

|

| ↓ | |

|

|

| ↓ | |

|

|

| ↓ | |

|

|

|

|

Characteristics

Characteristics

| Parameter |

VK 200 50 Hz |

VK 200 60 Hz |

Measurement unit |

|---|---|---|---|

| Frequency | 50 | 60 | Hz |

| Phase | 1 | 1 | ˜ |

| Voltage | 230 | 230 | V |

| Power | 107 | 132 | W |

| Current | 0.47 | 0.58 | A |

| Sound pressure level at 3 m distance | 46 | 46 | dBА |

| Maximum air capacity | 780 | 890 | m³/h |

| EC motor | no | no | - |

| RPM | 2660 | 2765 | min-1 |

| Protection rating | IP X4 | IP X4 | - |

| Design | centrifugal | centrifugal | - |

| Duct diameter | 200 | 200 | mm |

| Casing material | plastic | plastic | - |

| Width | 354 | 354 | mm |

| Weight | 3 | 3 | kg |

| Height | 340 | 340 | mm |

| SEC Class | B | - | - |

| Outdoor mounting | no | no | - |

| Sound-insulated casing | no | no | - |

| Duct | for round air ducts | for round air ducts | - |

| Type | exhaust, supply | exhaust, supply | - |

| Mounting | Inline | Inline | - |

| * | To meet the requirements of ErP 2018, a speed controller and local demand control typology must be applied (connect a sensor). | To meet the requirements of ErP 2018, a speed controller and local demand control typology must be applied (connect a sensor). | - |

Capacity diagram

Capacity diagram

- Selection method:

- Air flow:

- Pressure:

Operating point

- Air flow: --

- Pressure: ---

Files archieve

Downloads

Select document type

Dimensions

Characteristics

| Parameter | Value | Measurement unit |

|---|---|---|

| ∅D | 200 | mm |

| ØD1 | 340 | mm |

| B | 354 | mm |

| L | 276 | mm |

| L1 | 30 | mm |

| L2 | 30 | mm |

| L3 | 40 | mm |

ADDITIONAL TECHNICAL DATA

ADDITIONAL TECHNICAL DATA

| Sound-power level, A - weighted | Octave-frequency band [Hz] | LpA, 3 m dBA | LpA, 1 m dBA | |||||||||

| Hz | Gen. | 63 | 125 | 250 | 500 | 1000 | 2000 | 4000 | 8000 | |||

| LwA to inlet | dBA | 85 | 47 | 74 | 81 | 77 | 77 | 78 | 70 | 59 | 65 | 75 |

| LwA to outlet | dBA | 83 | 44 | 73 | 77 | 75 | 75 | 78 | 70 | 60 | 63 | 73 |

| LwA to environment | dBA | 66 | 27 | 48 | 59 | 61 | 61 | 59 | 51 | 39 | 46 | 56 |

Designation key

Designation key

| Series | Duct diameter [mm] | Options | |

| VENTS VK | S: high-powered motor | 100; 125; 150*; 200; 250; 315 |

Q: low-powered motor. Duo: double-speed motor. U: speed controller with electronic thermostat and temperature sensor integrated into the air duct. Equipped with power cord and IEC C14 electric plug. Temperature-based operation logic. Un: speed controller with electronic thermostat and external temperature sensor fixed on 4 m cable. Equipped with power cord and IEC C14 electric plug. Temperature-based operation logic. U1: speed controller with electronic thermostat and temperature sensor integrated into the air duct. Equipped with power cord and IEC C14 electric plug. Timer-based operation logic. U1n: speed controller with electronic thermostat and external temperature sensor fixed on 4 m cable. Equipped with power cord and IEC C14 electric plug. Timer-based operation logic. P: built-in smooth speed controller and power cord with IEC C14 electric plug. V: built-in speed switch (for models with double-speed motors). R: power cord with IEC C14 electric plug. |

* VK 150 model is compatible with the air ducts both Ø 150 and 160 mm

Video

Video

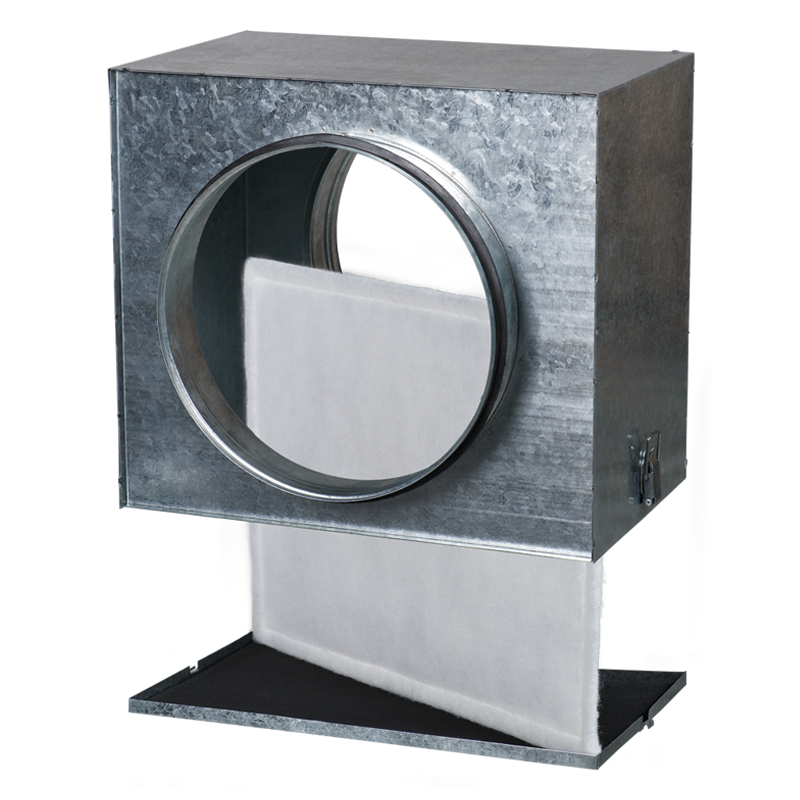

Accessories

Domestic fans

Domestic fans  Industrial and commercial fans

Industrial and commercial fans  Single-room ventilation systems with heat recovery

Single-room ventilation systems with heat recovery  Air handling units

Air handling units  Air heating systems

Air heating systems  Air sterilizers

Air sterilizers  Smoke extraction and ventilation

Smoke extraction and ventilation  Accessories for ventilating systems

Accessories for ventilating systems  Electrical accessories

Electrical accessories  Ventilation ducts and fittings

Ventilation ducts and fittings  Air distribution components

Air distribution components  Ventilation kits and vents

Ventilation kits and vents