| DESCRIPTION |

MODIFICATIONS |

- The VUT R TN H EC/ VUT R TN EH EC are fully featured air handling units designed to ensure air filtration, fresh air supply and stale air extract.

- During operation the extract air heat is transferred to the supply air stream by the rotary heat exchanger.

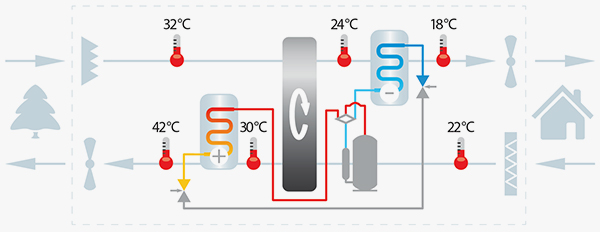

- A ventilation system comprising a rotary heat exchanger and a heat pump can effectively supply fresh air at a comfortable temperature to the premises thereby reducing the load on the existing heating or cooling systems in the building.

- When the heat pump and the rotary heat exchanger work simultaneously the energy released to the energy consumed ratio is 1:8 meaning that each kilowatt of electricity generates up to 8 kW of heat output.

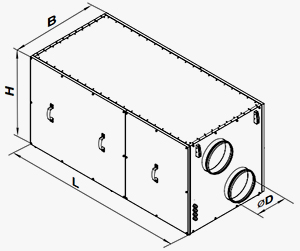

- All the models are designed for connection to Ø 160 or 250 mm round air ducts.

|

- The VUT R TN H EC models are equipped with a rotary heat exchanger and a heat pump without preheating.

- The VUT R TN EH EC models are equipped with a rotary heat exchanger and a heat pump as well as a preheater.

|

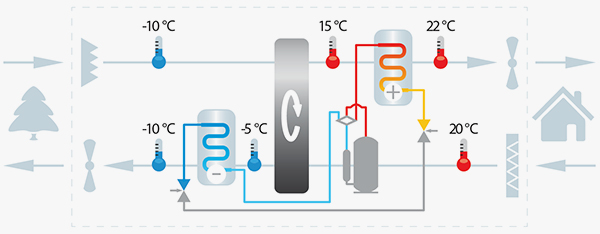

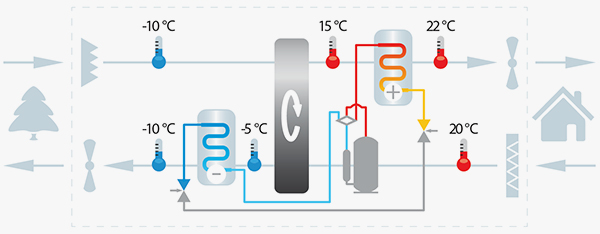

| TWO-STAGE ENERGY SAVING SYSTEM: |

- Stage 1: Heat energy recovery by means of the rotary heat exchanger (up to 85% efficiency).

- Stage 2: Supply air heating by the heat pump utilizing the low-potential extract air thermal energy.

|

|

|

Advantages:

- High energy efficiency.

- Low energy consumption.

|

- Energy-saving solution.

- Maximum occupant comfort.

|

| CASING |

MOTOR |

- The casing framework consists of three-layer panels made of aluzinc and internally filled with a 25 mm mineral wool layer for reliable heat- and soundinsulation.

- Due to the specially designed removable side panels the unit requires little service space and access to the unit components.

|

- The units are equipped with high-efficient direct current electronically commutated (EC) motors with an external rotor and backward curved impeller blades.

- As of today such motors are the most state-of-the-art and progressive energy saving solution.

- EC motors are featured with high performance and well controllable speed range.

- Premium efficiency reaching 90% is the definite advantage of electronically-commutated motors.

|

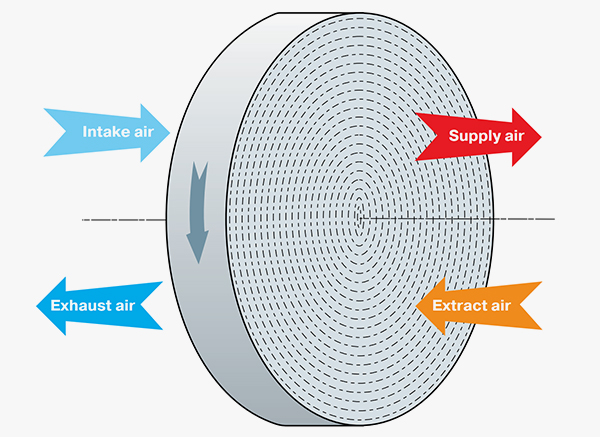

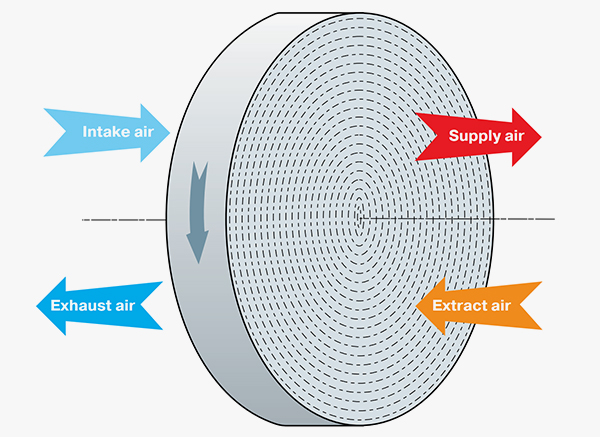

| ROTARY HEAT EXCHANGER |

- The rotary heat exchanger is a rotating short cylinder filled with multiple layers of corrugated aluminium strip in such a way so as to ensure free passage of the supply and exhaust air streams.

- As the wheel rotates the contact patch repeatedly moves from the intake to the extract air stream causing heating and cooling cycles thus transferring heat and humidity from the warmer air stream to the cooler one.

- The rotary heat exchanger transfers the sensible and latent heat from the warm air stream to the cool one enabling partial moisture transport back to the premises.

- By virtue of design the rotary heat exchanger is hardly prone to freezing (the chances of ice buildup within the normal temperature and humidity range are almost zero).

|

| FILTER |

- The unit has two integrated class G4 filters to filtrate intake and extract air.

- The unit can be supplied with a class F7 supply filter (option).

|

| |

| |

| |

| |

| |

| |

| |

|

| Rotary heat exchanger operating logic |

| HEAT PUMP |

HEATER |

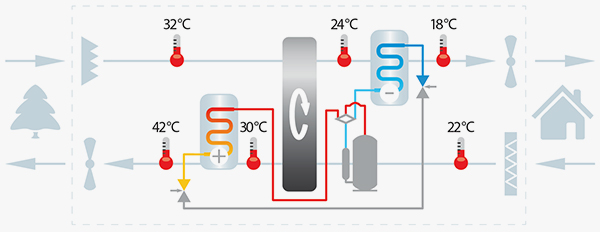

- The unit is cooled by a reversible heat pump which warms up or cools down the air as necessary.

- The rotary air compressors used combine high performance with low noise levels.

- The units utilize the R410A high-tech two-component cooling agent as the heat pump working fluid offering exceptional thermodynamic properties without depleting the ozone layer.

- The highly efficient rotary heat exchanger recovers most thermal energy contained in the extract air and transfers it to the intake air.

- The heat pump transfers the remaining part of the low-potential extract air thermal energy to the intake air stream maintaining the user-defined room air temperature.

|

- The VUT R TN EH EC units are equipped with a posistor electric heater which pre-heats intake air when the ambient temperature drops below the normal range.

- Preheating reduces the number of heat pump defrosting cycles thus increasing the overall operational efficiency of the unit.

- The heater is divided into two active elements for added power consumption economy without compromising the heating capacity.

|

| CONTROL AND AUTOMATION |

- The unit is equipped with a built-in automation system and the A17 (th-Tune) or A18 (pGD1) multifunctional sensor control panel.

|

| |

|

|

| A17 control panel |

A18 control panel |

| The standard delivery set includes a 10 m cable for connection to the control panel. |

| MAIN OPERATING MODES OF THE UNIT: |

|

| |

|

|

Auto mode:

The unit runs in the automatic supply and exhaust mode maintaining the userdefined room temperature.

Heating mode:

The unit runs in the supply and exhaust mode maintaining the room temperature above the pre-set threshold level. As soon as the room temperature drops below the pre-set threshold the heat exchanger and the heat pump are activated (in the heating mode).

Cooling mode: Cooling mode:

The unit runs in the supply and exhaust mode maintaining the room temperature below the pre-set threshold level. As soon the room temperature exceeds the pre-set threshold the rotary heat exchanger and the heat pump are activated (in the cooling mode).

Heat Recovery mode: Heat Recovery mode:

The unit runs in the supply and exhaust mode maintaining the room temperature by means of the rotary heat exchanger only without engaging the heat pump. This mode is activated automatically while in the Auto, Heating or Cooling mode if the heat exchanger alone can maintain the user-defined room temperature without engaging the heat pump. This mode can also be entered manually via the controller menu or the A18 (рGD1) control panel.

Ventilation mode: Ventilation mode:

The unit runs in the supply and exhaust mode without maintaining the pre-set room temperature. The heat exchanger and heat pump operation is blocked. Room temperature adjustment is not available. This operation mode is only available via the А18 (pGD1) control panel.

|

Defrosting mode:

This mode is enabled automatically (upon elapsing of the pre-set time range and/ or reaching the temperature threshold) while running in the Auto and Heating modes to prevent icing of the heat pump heat exchanger. While in the Defrosting mode the fan operation is blocked. Upon the Defrosting mode deactivation the unit reverts to the previous operation mode automatically. While in the Defrostingmode the operation modes switching is not available.

Preheating mode: Preheating mode:

While running in the Auto or Heating modes at low ambient temperatures the intake air fed into the unit is warmed up by the electric preheater. This mode is enabled automatically upon the ambient temperature dropping below -8 °C. If the outdoor air temperature reaches above -8 °C the Preheating mode is disabled. This mode is only available in factory configurations of the VUT R TN EH EC models equipped with an electric heater. The Preheating mode implementation in a VUT R TN H EC requires upgrading the unit with a seriesproduced electric heater (purchased separately) installed into the unit casing. The heater may only be installed by a service provider certified by the unit manufacturer.

Recirculation mode: Recirculation mode:

This optional mode requires upgrading the unit with an external recirculation valve (purchased separately). The recirculation mode is enabled automatically at subzero ambient temperatures allowing a considerable reduction of unit energy consumption due to a partial redirection of the exhaust air into the supply duct of the unit.

|

| INTELLIGENT CONTROL SYSTEMS: |

|

| |

|

|

Limit Function technology: Limit Function technology:

Automatic air flow reduction to maintain the user-defined temperature. If the unit cannot execute the user-defined room temperature setting after running in the Auto or Heating mode for 20 minutes the air flow rate (fan speed) is reduced automatically. The unit reverts to the original fan operation mode upon reaching the target air temperature as defined by the user. While in the Limit Function mode the air flow adjustment is not available.

Warming-Up technology: Warming-Up technology:

Blocks cold air supply into the premises in the Auto or Heating mode. Implemented by warming up the heat pump heat exchanger in the supply air duct while the supply fan remains deactivated. The Warming-Up mode is enabled after the Defrosting mode as well as upon the first start if the outdoor air temperature is below +10 °C. Upon completion of the Warming-Up cycle the unit reverts to the original Auto or Heating mode.

Higher Speed technology: Higher Speed technology:

Automatic increase of the extract air flow capacity while in the Cooling mode to prevent excessive pressure build-up in the heat pump. The extract fan reverts to the initial speed once the pressure has dropped to normal.

Smart Safe technology: Smart Safe technology:

Automatically protects the unit from operating outside the safe performance range. The unit is equipped with an intelligent hardware protection system ensuring its safe and reliable performance within the permissible range of ambient temperature conditions. Therefore, the unit is able to adjust operating parameters or disable certain units and assemblies to compensate for abnormal operating conditions in order to prevent equipment failure.

Heat Pump Protection technology: Heat Pump Protection technology:

Automatically prevents heat pump failure:

- Protection against abnormally high or low pressure build-up. If the coolant pressure reaches beyond the safe performance range the pressure sensors send signals to the unit controller to power off the heat pump compressor. The compressor power is restored once the pressure has reverted to normal.

- Compressor thermal overheating protection. The compressor is powered off when its casing temperature becomes abnormally high. The power is restored once the casing temperature has dropped to the normal performance range.

- Delayed Start technology: Protects the compressor from cycling (by blocking too frequent activation/ deactivation of the compressor).

Serviceability technology: Serviceability technology:

The design solutions provide for easy access to the unit parts and components, facilitate its maintenance and replacement of the consumables and wear parts and ensure high serviceability of the entire air handling unit.

Fresh Air technology: Fresh Air technology:

Ensures clean air supply into the premises. The unit is equipped with a class G4 filter (a class F7 filter is available as an option). The control system monitors the filter performance automatically and generates replacement signals as necessary.

Ozone Protection technology: Ozone Protection technology:

The heat pump utilizes the R410A high-tech two-component cooling agent which does not deplete the ozone layer.

|

Save Energy technology: Save Energy technology:

A comprehensive engineering and technical approach to reducing the unit energy consumption which comprises the following elements:

- a posistor electric preheater with two active elements;

- an upgraded thermal insulation of the supply chamber;

- an integral high-performance air-to-air heat pump;

- an adjustable fan speed;

- automatic heat exchanger and heat pump activation/ deactivation;

- electric heater deactivation in the Defrosting mode;

- the «Intelligent-vents-software» unit control software for maintaining optimum performance characteristics at low energy consumption based on the exclusive control algorithms

Low Noise technology: Low Noise technology:

A comprehensive engineering and technical approach to reducing the unit noise levels during operation comprising the following elements:

- a heat pump integrated into the sound-insulated unit casing;

- adjustable-speed fans;

- a low-noise rotary compressor.

Autorestart technology:

The unit memorizes the current operation mode in case of a power outage.

Simple Use technology: Simple Use technology:

The units are pre-assembled at the factory and are ready for operation. The installation and maintenance costs are reduced to a bare minimum. The unit operation does not require any special training due to a simple and intuitive interface.

CO2 Control technology: CO2 Control technology:

Maintains the CO2 level in the ventilated premises below the user-defined threshold level. Should the CO2 concentration in the premises airspace become abnormally high the unit increases the air exchange rate automatically. This option is available only with the external CO2 sensor with a 0-10 V output signal (purchased separately).

RH Control technology: RH Control technology:

Maintains the relative humidity level in the ventilated premises below the user-defined threshold level. Should the relative humidity become abnormally high the unit increases the air exchange rate automatically. This option is available only with the A17 (th-Tune) control panel in a special configuration or the external relative humidity control sensor with a 0-10 V output signal (purchased separately).

Rapid Access to Set Mode technology: Rapid Access to Set Mode technology:

The bigger the difference between the ambient temperature and the user-defined setpoint the faster the heat pump activates.

|

|

|

| Unit operation in the Heat Recovery and Air Heating ventilation mode |

Unit operation in the Heat Recovery and Air Cooling ventilation mode |

| MOUNTING |

|

- The unit is designed for mounting to a horizontal plane, suspension to a ceiling or wall mounting by means of brackets.

- Service access must be provided on the side panel side.

|

|

| ACCESSORIES TO AIR HANDLING UNITS: |

|

| |

|

Domestic fans

Domestic fans  Industrial and commercial fans

Industrial and commercial fans  Single-room ventilation systems with heat recovery

Single-room ventilation systems with heat recovery  Air handling units

Air handling units  Air heating systems

Air heating systems  Air sterilizers

Air sterilizers  Smoke extraction and ventilation

Smoke extraction and ventilation  Accessories for ventilating systems

Accessories for ventilating systems  Electrical accessories

Electrical accessories  Ventilation ducts and fittings

Ventilation ducts and fittings  Air distribution components

Air distribution components  Ventilation kits and vents

Ventilation kits and vents

Cooling mode:

Cooling mode: Heat Recovery mode:

Heat Recovery mode: Ventilation mode:

Ventilation mode:

Preheating mode:

Preheating mode: Recirculation mode:

Recirculation mode: Limit Function technology:

Limit Function technology: Warming-Up technology:

Warming-Up technology: Higher Speed technology:

Higher Speed technology: Smart Safe technology:

Smart Safe technology: Heat Pump Protection technology:

Heat Pump Protection technology: Serviceability technology:

Serviceability technology: Fresh Air technology:

Fresh Air technology: Ozone Protection technology:

Ozone Protection technology: Save Energy technology:

Save Energy technology: Low Noise technology:

Low Noise technology:

Simple Use technology:

Simple Use technology: CO2 Control technology:

CO2 Control technology: RH Control technology:

RH Control technology: Rapid Access to Set Mode technology:

Rapid Access to Set Mode technology: