VENTS TT Silent-M EC series

- Description

- Modifications

- Capacity diagram

- Downloads

- Designation key

- BIM

Description

Description

| APPLICATION |

|

- The new VENTS TT Silent-M EC duct fan series is provided with a special noise-insulated casing which ensures silent operation and excellent aerodynamic characteristics.

- Compatible with Ø100 up to Ø315 mm air ducts.

- The VENTS TT Silent-M EC fans combine the versatility and outstanding performance of both axial and centrifugal fans producing a powerful air flow and high pressure while retaining the signature energy-efficiency and response of EC motors.

|

- Several fans can be integrated into a single computer-controlled system with sensor feedback combined with speed control across the entire dynamic range.

- Application: Combined supply and exhaust ventilation systems of various commercial and industrial spaces with stringent noise requirements (such as libraries, conference halls, classrooms, kindergarten playrooms etc.).

|

| DESIGN |

|

- The external casing is made of steel with a polymer coating.

- The internal casing perforations conduct sound waves and direct them at the noise-absorbing material at a specific angle.

- Noise and heat insulation is ensured by a mineral wool layer 50 mm in thickness.

- Wideband noise control is achieved by means of special casing perforation and the use of noise-absorbing material.

- The inner casing and the impeller are made of durable high-quality plastic.

|

- Conical impellers with specially profiled blades help boost angular velocity of the air flow resulting in higher pressure and air capacity compared to the conventional designs.

- The combination of a diffuser, a specially designed impeller and flow straightener vanes at the fan outlet allow for an optimum flow distribution to achieve high capacity and increased air pressure without generating excessive noise.

- The fan casing is equipped with an external water-tight terminal box for electrical connections.

|

| MOTOR |

|

- The fans feature high-efficiency electronically commutated (EC) direct current motors.

- These state-of-the-art units offer excellent energy efficiency.

|

- EC motors combine high performance and optimum control across the entire speed range.

- The performance efficiency of the electronically commutated motors reaches 90 %.

|

| SPEED CONTROL |

|

- The fans are controlled by means of a 0-10 V control signal while the performance regulation is based on the feedback from the temperature, smoke and other sensors as well as other vital parameter settings.

- As the control signal changes the EC fan adjusts the speed to supply the exact amount of air required by the ventilation system.

- The maximum fan speed does not depend on the electric mains frequency enabling compatibility with both 50 Hz and 60 Hz networks.

|

- The fans can be easily combined into a single computer-controlled network.

- Special software allows for precise control over the operating parameters of the network units.

- All the system parameters can be monitored from a computer screen allowing to program operating parameters for each fan on the network individually.

|

| MOUNTING |

|

- The fans are designed to be used with round air ducts.

- The fan casing has mounting brackets for convenient installation onto the floor, walls or ceiling.

- The ducts can be fitted at any angle relative to the fan axis.

- Make sure to provide sufficient maintenance access during fan installation.

|

- Electrical connection and installation must be performed in accordance with the instruction manual and the electrical connections diagram applied to the terminal box.

- A single system may have several fans installed in parallel to boost the output capacity or in series to boost the working pressure.

|

Capacity diagram

Capacity diagram

Designation key

Designation key

| Series |

Casing material |

Air ducts diameter |

Motor type |

| VENTS TT SILENT-M: mixed-type duct fan in casings with noise and heat insulation |

M: metal |

100; 125; 150; 160; 200; 250; 315 |

EC: synchronous electronically commutated motor |

Domestic fans

Domestic fans  Industrial and commercial fans

Industrial and commercial fans  Single-room ventilation systems with heat recovery

Single-room ventilation systems with heat recovery  Air handling units

Air handling units  Air heating systems

Air heating systems  Air sterilizers

Air sterilizers  Smoke extraction and ventilation

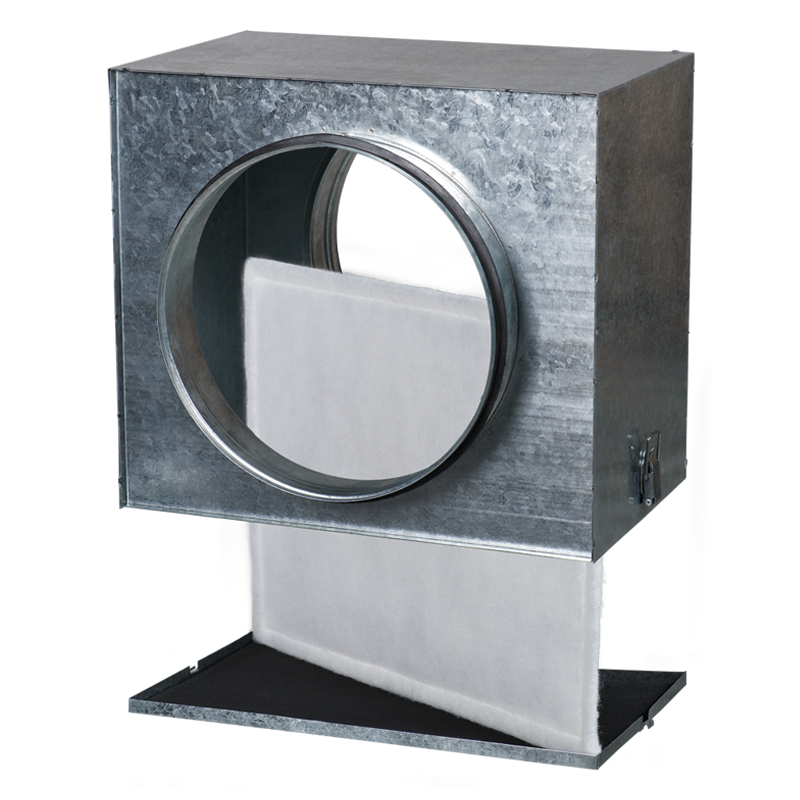

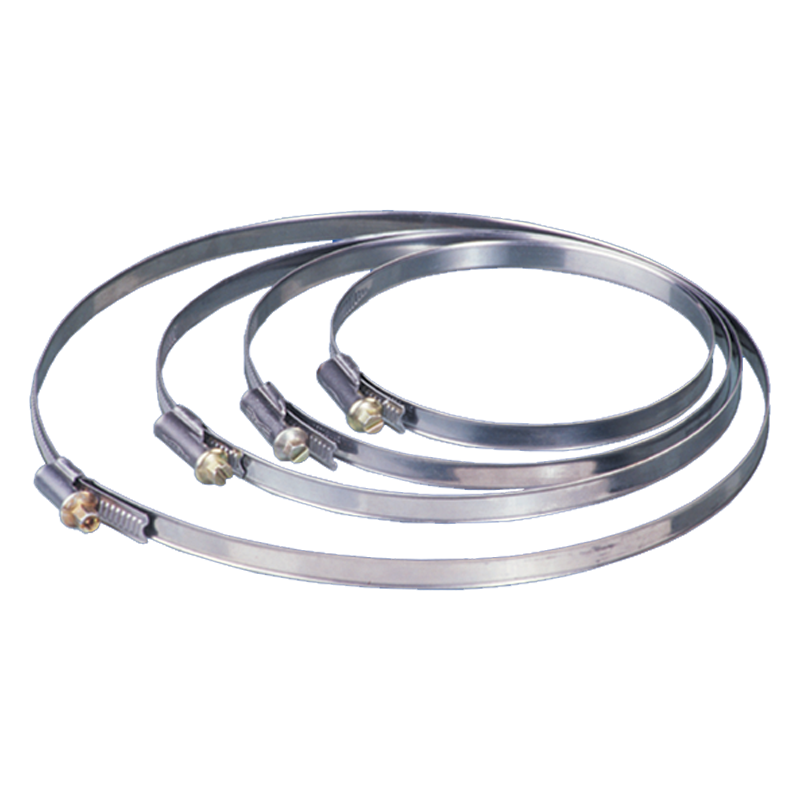

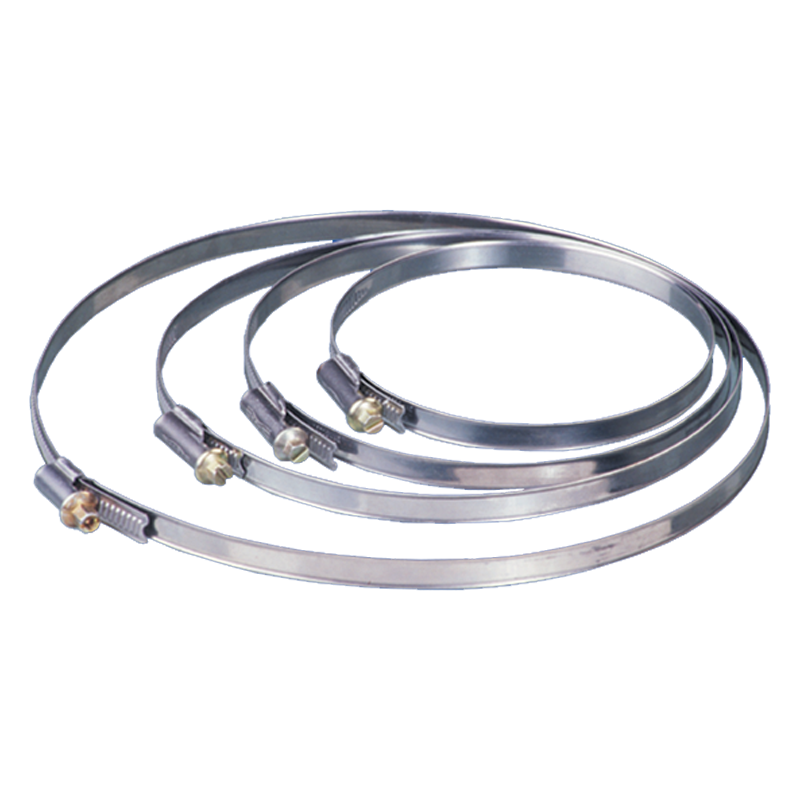

Smoke extraction and ventilation  Accessories for ventilating systems

Accessories for ventilating systems  Electrical accessories

Electrical accessories  Ventilation ducts and fittings

Ventilation ducts and fittings  Air distribution components

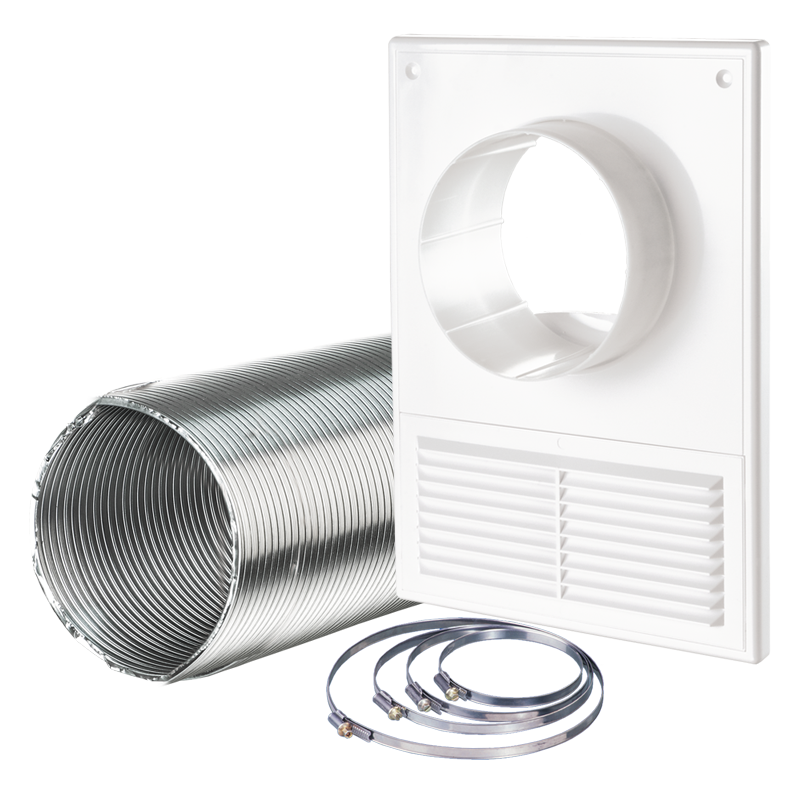

Air distribution components  Ventilation kits and vents

Ventilation kits and vents