VENTS VUT 300 E2V EC air handling units with heat recovery

- Description

- Modifications

- Capacity diagram

- Downloads

- Legend

Description

Description

| DESCRIPTION |

|

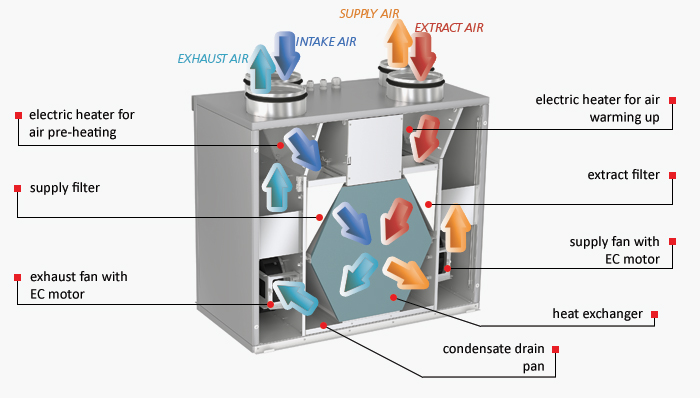

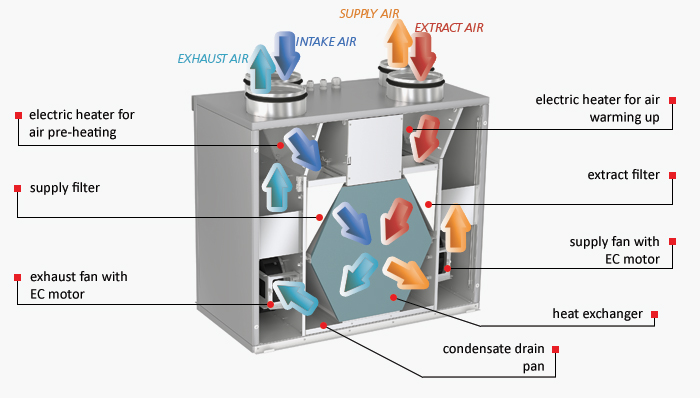

- The air handling unit VUT 300 E2V EC with heat recovery is the fully-featured ventilation unit which ensures air filtration, fresh air supply and stale air extract.

- The heat contained in the extract air is recuperated in the plate counter-flow heat exchanger to warm up supply air.

|

- The unit is designed for energy efficient ventilation of cottages and flats in the cold climatic conditions.

- The heat exchanger freezing protection is ensured due to the pre-heating electric heater on the intake side.

- Compatible with round Ø 150 or 160 mm air ducts.

|

| UNIT DESIGN |

|

| FANS |

CASING |

- High-efficient electronically-commutated direct current motors with external motor and impellers with backward curved blades.

- Such motors are the most state-of-the-art energy-saving solution.

- EC motors are featured with high performance and total speed controllable range.

- Any of three fan speeds may be adjusted with the remote controller.

- The supply and extract fan speeds are adjustable during the system setup.

|

- Made of double-skinned aluzinc, internally filled with 20 mm mineral wool heat- and sound-insulating layer.

|

| FILTER |

- Supply and extract air flows are purified through two bag filters with filtering class G4.

- A replaceable filter with filtering class F7 is optionally available.

|

| CONTROL AND AUTOMATION |

| HEAT EXHANGER |

|

- Counter-flow polystyrene heat exchangers with high heat recovery efficiency (up to 95%).

- The drain pan under the heat exchanger block ensures condensate removal.

- The heat exchanger has freezing protection with the electric heater on the intake side.

- The special heat exchanger freeze protection logic provides temporary fan speed slowdown at the outdoor temperatures below -30 °C if the pre-heating power is not sufficient to maintain the best heat recovery efficiency.

- The removable heat exchanger facilitates cleaning.

|

| HEATER |

- The unit is exchanged with two electric heaters.

- The first heater is located upstream of the heat exchanger to heat the intake air up to the temperature that excludes the heat exchanger freezing and to maintain the maximum heat recovery efficiency.

- The second heater is located downstream of the heat exchanger to warm up supply air flow up to the set temperature.

- The heating electric elements have active overheating protection controlled by the temperature sensor in the air duct and two overheating thermostats. The first one is actuated at +50 °C and has automatic reset and the second one is actuated at +90 °C and has manual reset.

- Air supply to the electric heating elements at the end of the heating cycle ensures cooling of the electric heating elements.

|

| MOUNTING |

- The unit is designed for inner mounting in glazed balconies, auxiliary premises, in the attics and is allowed for use at the ambient air temperature not below -15 °C.

- If the unit is intended to operate at low outside temperatures, its drain pipe must be heat insulated to prevent condensate freezing.

- The unit must be fixed to the wall with anchor bolts or mounted on the floor in a position that enables condensate drainage.

- While mounting the unit provide service access on the front panel side. The panel may be fully removed if required.

|

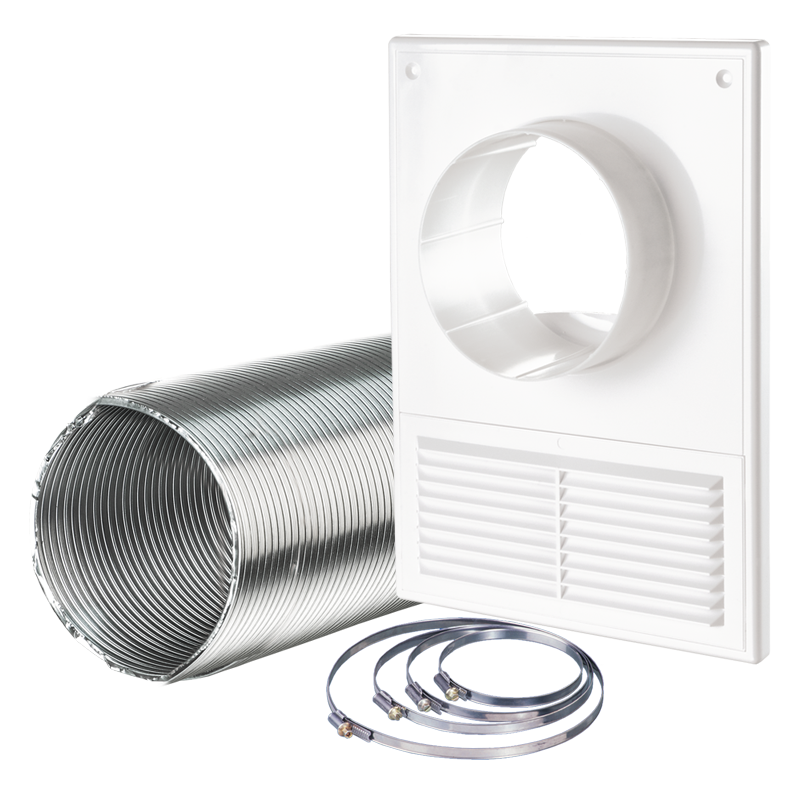

| EXTRA ACCESSORIES |

| |

- The SR duct silencers are recommended to install in the supply air duct to ensure extra sound attenuation.

|

|

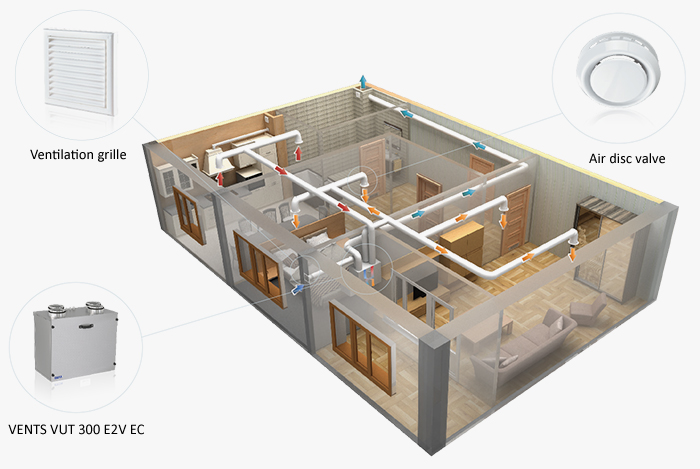

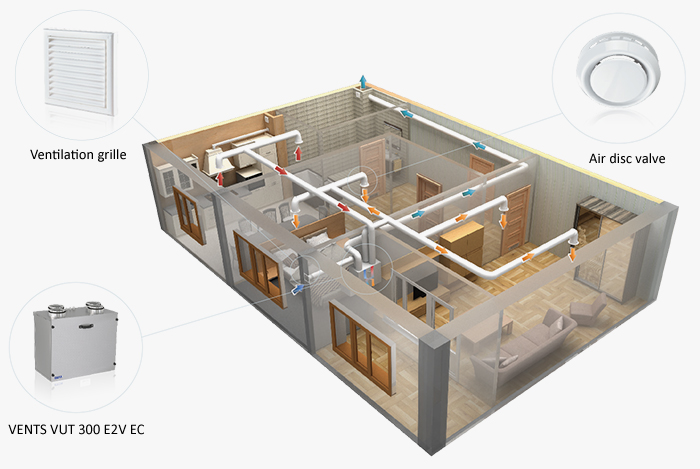

| APPLICATION EXAMPLE: |

|

|

Capacity diagram

Capacity diagram

Legend

Legend

|

Series |

|

Rated air capacity, m3/h |

|

Air ducts diameter |

|

Heater type and number |

|

Duct connection |

|

Motor type |

VENTS VUT

|

|

300 |

|

_ – 150

2 – 160 |

|

E2 - electric heater, 2 items |

|

V - vertical |

|

EC - synchronous electronically commutated motor |

Domestic fans

Domestic fans  Industrial and commercial fans

Industrial and commercial fans  Single-room ventilation systems with heat recovery

Single-room ventilation systems with heat recovery  Air handling units

Air handling units  Air heating systems

Air heating systems  Air sterilizers

Air sterilizers  Smoke extraction and ventilation

Smoke extraction and ventilation  Accessories for ventilating systems

Accessories for ventilating systems  Electrical accessories

Electrical accessories  Ventilation ducts and fittings

Ventilation ducts and fittings  Air distribution components

Air distribution components  Ventilation kits and vents

Ventilation kits and vents