| APPLICATION |

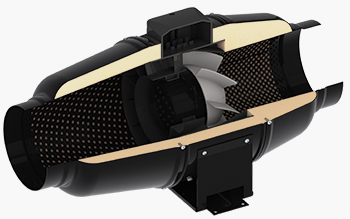

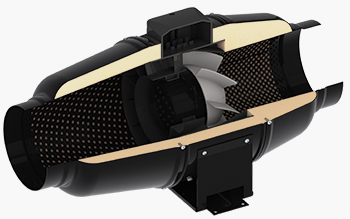

- New inline VENTS TT Silent-M fans are enclosed in a specially designed sound-insulated casing that ensures silent fan operation in combination with high aerodynamic characteristics.

- The fans are compatible with round air ducts from Ø 100 up to 450 mm.

- The VENTS TT Silent-M fans combine wide capabilities and high performance characteristics of both axial and centrifugal fans, thus providing powerful air stream and high pressure.

|

- The VENTS TT Silent-M fans are recommended as a component of the air handling systems for various commercial and industrial premises with high requirements to noise level, i.e. in libraries, conference halls, educational institutions, kindergartens, etc.

|

| DESIGN |

- The external casing is made of polymer-coated steel.

- The inner casing perforation let sound waves pass through the holes and fall at a specific angle to the sound-absorbing layer.

- The casing is internally heat- and the sound-insulated with 50 mm mineral wool layer.

|

- The specially perforated casing and sound-absorbing material provide sound attenuation in a broad frequency band.

- The inner casing and the impeller are made of high-quality durable plastic.

|

|

- Due to the conic impeller and special blade profiling the circumferential air speed increases thus providing higher air pressure and capacity as compared to standard axial fans.

|

- The diffuser, the specially profiled impeller and the directing vanes at outlet from the fan casing distribute air flow in such a way as to attain the best combination of high performance and high pressure at low noise level.

- The fan casing is equipped with an airtight terminal box for connection to power mains.

|

| MOTOR |

|

|

- The ball bearings extend the motor service life up to 40 000 hrs. at non-stop operation.

- The motor has IP X4 ingress protection rating.

|

| CONTROL |

- The double-speed motors are controlled with a built-in switch («V»option) or an external switch for multi-speed fans (available upon separate order).

|

|

| TT Silent-M fan with a three-position speed switch |

- A built-in speed controller (P option), an external TRIAC or autotransformer speed controller (available upon separate order) enable smooth motor speed control when connected to the maximum speed terminal.

|

- T option models are equipped with an adjustable turn-off delay timer, adjustable from 2 to 30 minutes.

|

|

| TT Silent-M fan with a built-in speed controller |

| MOUNTING |

- The fan may be mounted at any place and at any angle within the ductwork system.

|

- Several fans may be installed in one system in parallel to attain higher air capacity or in series to increase operating pressure in the system.

- The fan casing is equipped with fixing brackets for fastening to the floor, wall or ceiling.

|

| THE FAN WITH ELECTRONIC MODULE OF THE TEMPERATURE SENSOR AND SPEED CONTROLLER («U» OPTION) |

- The ideal solution for ventilation of the premises with high demands to permanent temperature control e.g. greenhouses.

|

- The fan with the electronic temperature and speed control module provides automatic control of motor speed (air capacity) depending on the air temperature in the air duct or in the room.

|

| The front panel of the electronic module has the following control knobs: |

|

- speed control knob for setting the motor speed;

- thermostat control knob for setting the temperature set point;

|

- thermostat indicator light.

|

| The fan is available in two modifications: |

|

- with a temperature sensor integrated inside the fan air duct (U/U1 option);

|

- with an external temperature sensor fixed on the cable, 4 m long (Un / U1n option).

|

|

|

| CONTROL LOGIC OF THE FAN WITH THE ELECTRONIC TEMPERATURE AND SPEED CONTROL MODULE |

- Set the desired air temperature (set point of the thermostat) with the thermostat control knob. Set the required minimum impeller speed (air flow) with the speed control knob. The motor switches to maximum speed (maximum air flow) as the temperature reaches and exceeds the set temperature set point.

|

- The motor switches to the pre-set lower speed as the temperature drops down below the set temperature point. To avoid the frequent motor speed changes, e.g. when the temperature in the supply air duct is equal to the threshold value, the switching delay time is activated.

|

| There are two switch delay control logics for various cases: |

- The temperature sensor-based switch delay (U option): the motor switches to higher speed as the air temperature exceeds 2°C above the set thermostat set point. The motor revers to the pre-set lower speed as the air temperature drops below the thermostat set point. This control logic is used to keep air temperature to within 2°C. In this case the motor speed switches are rare.

|

- The timer-based switch delay (U1 option): as the air temperature exceeds the set thermostat set point, the motor switches to higher speed and the switch delay timer is activated for 5 minutes. The motor reverts to lower speed as the air temperature drops down below the thermostat set point and only after the delay timer countdown. This pattern is used for exact air temperature control. The speed switches for the fan with U1 option are more frequent as compared to the fan with U option, however the minimum operating cycle at one speed is 5 minutes.

|

Domestic fans

Domestic fans  Industrial and commercial fans

Industrial and commercial fans  Single-room ventilation systems with heat recovery

Single-room ventilation systems with heat recovery  Air handling units

Air handling units  Air heating systems

Air heating systems  Air sterilizers

Air sterilizers  Smoke extraction and ventilation

Smoke extraction and ventilation  Accessories for ventilating systems

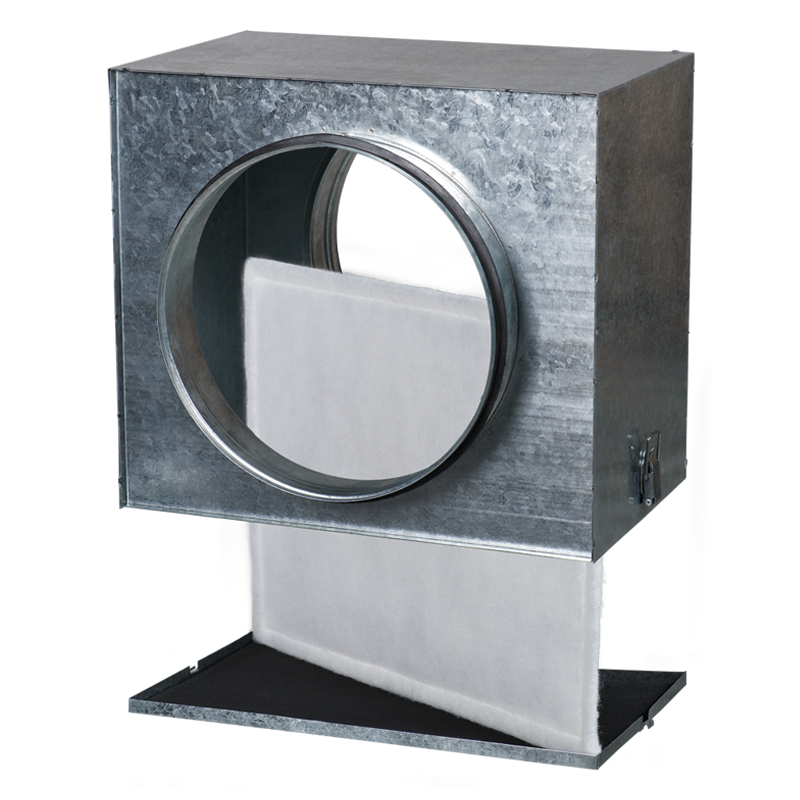

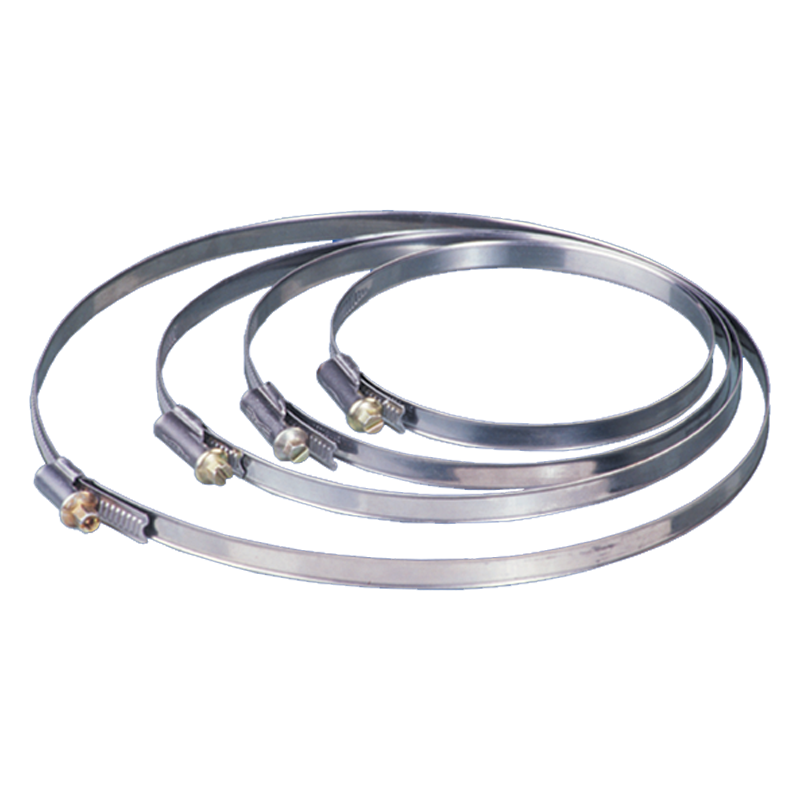

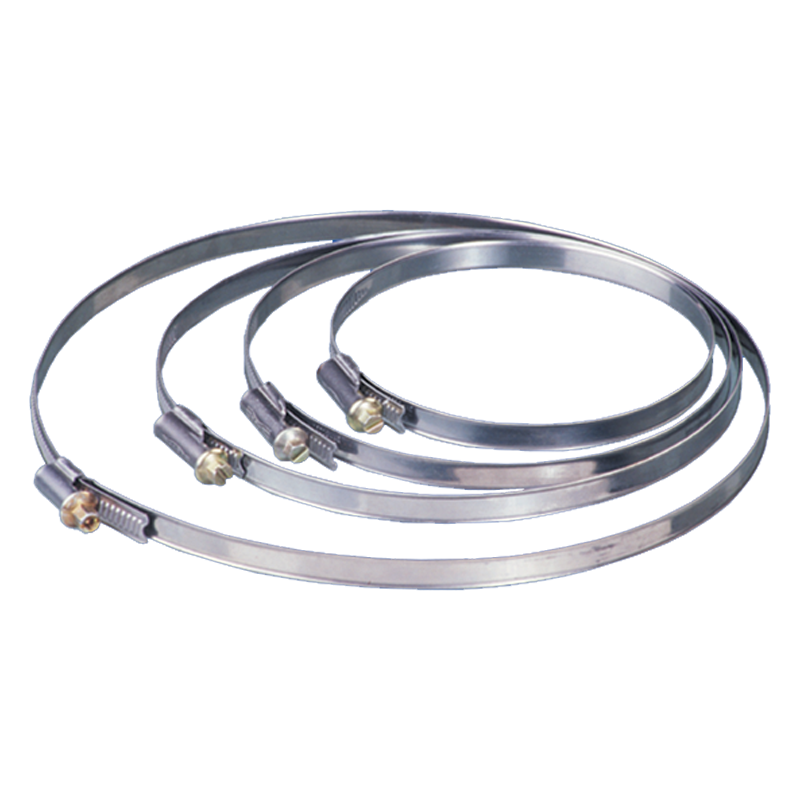

Accessories for ventilating systems  Electrical accessories

Electrical accessories  Ventilation ducts and fittings

Ventilation ducts and fittings  Air distribution components

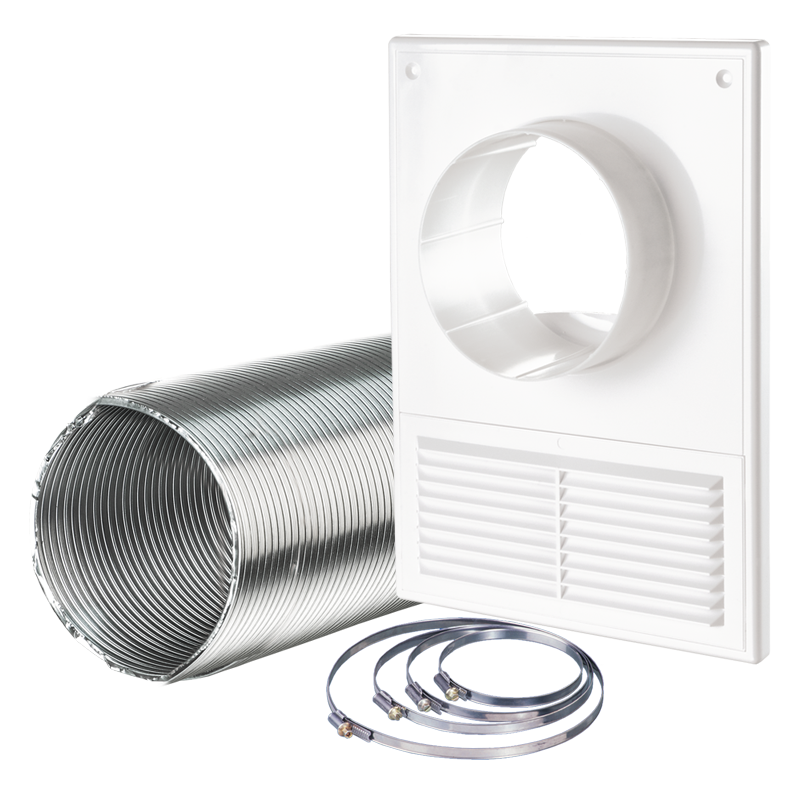

Air distribution components  Ventilation kits and vents

Ventilation kits and vents