Inline centrifugal fan VENTS VKM series

Inline centrifugal fans in steel casing with the air capacity up to 5260 m³/h.

Model features

Series of products

3D model

Gallery

- Description

- Modifications

- Capacity diagram

- Downloads

- Designation key

Description

Description

| APPLICATIONS | |

|

|

| DESIGN | |

|

|

| MOTOR | |

|

|

| SPEED CONTROL | |

|

|

| MOUNTING | |

|

|

| THE FAN WITH ELECTRONIC TEMPERATURE AND CONTROL MODULE (U OPTION) | |

|

|

|

|

| VENTS VKM fan catering ventilation example | |

Modifications

Capacity diagram

Capacity diagram

- Selection method:

- Air flow:

- Pressure:

Operating point

- Air flow: --

- Pressure: ---

Downloads

Downloads

Select document type

Designation key

Designation key

| Series | Air duct diameter | Options | |

| VENTS VKМ | S: high- powered motor |

100; 125; 150; 160; 200; 250; 315; 355; 400; 450 |

Е: low energy demand motor. Q: low-powered motor. Un: speed controller with an electronic thermostat and a temperature sensor fixed on a 4 m cable. Temperature-based operation logic. U2n: speed controller with an electronic thermostat and a temperature sensor fixed on a 4-meter cable. Temperature-based switching on/off. R1: power cord with a mains plug. P: integrated smooth speed controller. |

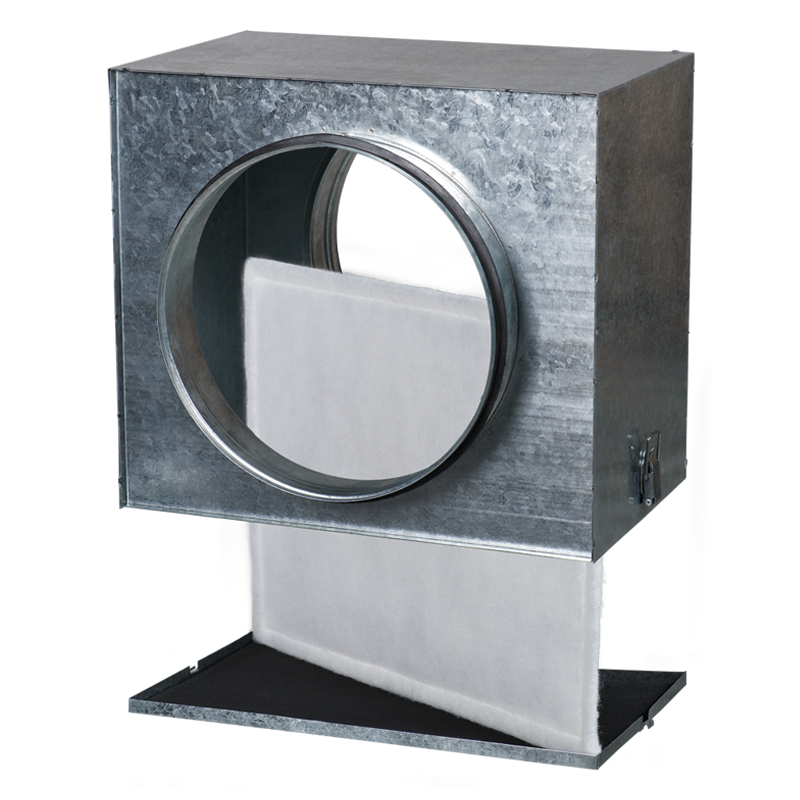

Accessories

Domestic fans

Domestic fans  Industrial and commercial fans

Industrial and commercial fans  Single-room ventilation systems with heat recovery

Single-room ventilation systems with heat recovery  Air handling units

Air handling units  Air heating systems

Air heating systems  Air sterilizers

Air sterilizers  Smoke extraction and ventilation

Smoke extraction and ventilation  Accessories for ventilating systems

Accessories for ventilating systems  Electrical accessories

Electrical accessories  Ventilation ducts and fittings

Ventilation ducts and fittings  Air distribution components

Air distribution components  Ventilation kits and vents

Ventilation kits and vents